Diving into the realm of innovative packaging design, our interview with Juan Campdera, CEO at Aktiva, introduces us to the world of molded pulp packaging.

With a focus on sustainability and functionality, Campdera sheds light on the captivating intricacies of this remarkable packaging solution. Molded pulp, or molded fiber packaging, emerges as a product of various fibrous materials like recycled paper, offcuts of cardboard, and natural fibers such as sugarcane bagasse, bamboo, and wheat straw.

These materials not only determine the packaging’s visual aesthetics, but also influence its physical attributes and surface texture. Originating in 1903, molded pulp manufacturing has evolved beyond its initial applications, like egg cartons, to encompass a range of sophisticated packaging designs.

Aligning with the growing consumer demand for sustainable alternatives, the interview delves into the creation process, the advantages over traditional packaging, and the unique design opportunities that molded pulp presents.

Based in the dynamic city of Barcelona, Aktiva is a brand experience design agency that places its emphasis on discerning, luxury, and esteemed brands within the industry. Enjoy the conversation and get ready to know more about molded pulp!

What is pulp packaging?

Juan Campdera:

“Molded pulp, also known as molded fiber packaging, is crafted using various fibrous materials such as recycled paper, cardboard offcuts, or natural fibers like sugarcane bagasse, bamboo, and wheat straw. These raw materials play a pivotal role in determining the packaging’s color, surface texture, and physical characteristics.

The origins of molded pulp manufacturing trace back to 1903 when the first patent was filed, and it has continuously evolved since then. Initially, its application was primarily limited to protective packaging like egg cartons and end caps.

Creating pulp packaging involves a series of steps.

The raw materials, including cardboard, newspaper, or natural fibers, are mixed with water to create a pulp slurry. This slurry is drawn through a mesh forming tool via vacuum until the desired thickness is attained. The wet components are then released from the mesh tools and dried.

To achieve smoother surfaces, the dried parts undergo pressing by heated metal tools. This is also the stage where debossed logos or artwork can be incorporated. Finally, the edges are trimmed, and any necessary holes or windows are die-cut.”

What aspects make it a viable alternative to traditional packaging solutions?

Juan Campdera:

“The journey of molded pulp manufacturing began with its first patent filing in 1903, and it has continuously evolved ever since. Initially, its main purpose was protective packaging, like egg cartons and end caps.

Recent times have seen technological advancements that enable the creation of more sophisticated packaging, boasting smoother surfaces and a stylish aesthetic. Currently, the meticulous attention to detail, high quality, and refined finishes have opened doors for selective product applications. Such projects span across diverse segments.

Pulp packaging emerges as a comprehensive alternative to conventional packaging. However, it does have limitations. Notably, production cost challenges arise for smaller quantities, and precautions must be taken against contact with moisture, including storage in humid environments such as refrigerators and freezers.”

From a design perspective, what opportunities does molded pulp offer?

Juan Campdera:

“Form vs function, without artifices.

This packaging type presents both elegance and challenges, driven by its mold-based manufacturing process. This compels us to craft a design that’s intrinsically self-supporting; its very form embodies its structure, imparting both strength and solidity. Concurrently, this structure assumes the task of safeguarding its contents. This unique attribute spawns captivating geometries, offering audacious designers a golden opportunity to forge distinctive and impactful aesthetics. This quality, in turn, emerges as a key draw.

Technical Prerequisites for Excellence.

Crafted via molds, molded pulp packaging sets itself apart from conventional folded cardboard boxes with its curved corners and intricate three-dimensional contours. As the pulp components take shape, they must disengage from their forming and pressing tools, rendering sharp 90-degree angles unfeasible. Instead, the design of pulp packaging incorporates 5-10 degree draft angles and corner radii, ensuring optimal functionality and aesthetics.”

Which products or industries can be interested in its use?

Juan Campdera:

“Versatile Protection and Appeal.

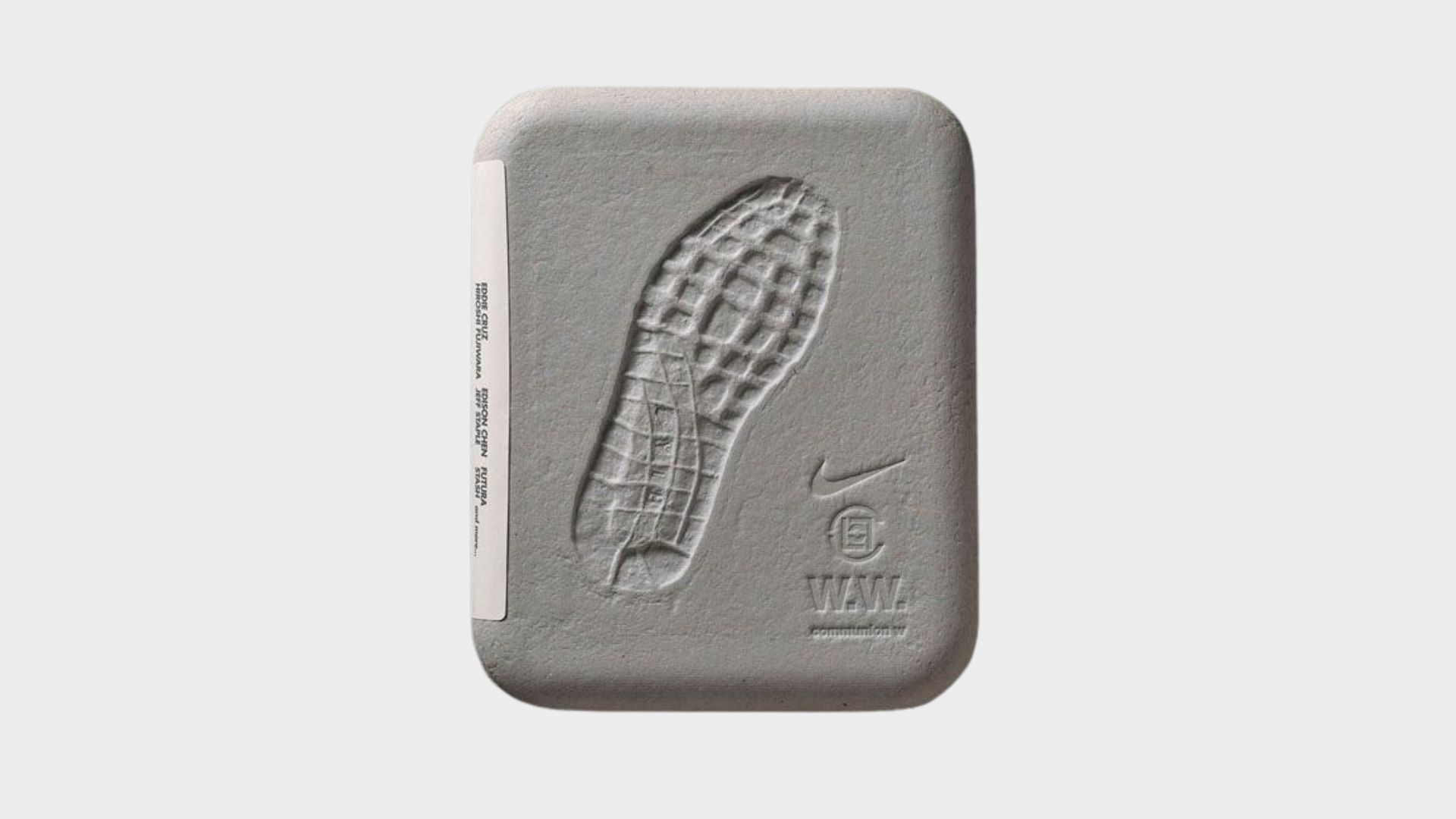

Molded pulp packaging finds widespread application in safeguarding electronics, delicate items, food and beverages, cosmetics, and diverse consumer goods. With its enhanced aesthetics, this packaging solution is now embraced across a broad spectrum of uses. Leading global brands like Nike, Sony, Ruinart, Chanel, and more prominently feature it across both specialized and general markets. Across all sectors, remarkable instances of its effectiveness abound.

Cost-Effective Solution.

Molded pulp packaging proves its worth in being cost-effective. While it demands a minimal production volume to justify the required mold costs, it emerges as an economical choice when quantities aren’t limiting factors. When compared to various packaging materials, molded pulp packaging stands out for its economic viability.”

As a branding and innovation agency, what role does such a solution play in terms of communication for your clients?

Juan Campdera:

“Seizing a Valuable Opportunity.

We engage clients in discussing the potential of pulp packaging. In today’s landscape, consumers—especially the younger like Generation Z and Alpha—are actively searching for remedies to the issue posed by excessive packaging production. Solutions center around reducing packaging volumes, crafting items from sustainable sources, enabling recyclability, and ensuring biodegradability for landfill scenarios. Pulp packaging impeccably fulfills these requisites.

Beyond Expectations.

This packaging not only meets but exceeds expectations, furnishing designers with the means to express authenticity and integrity through design. It distinguishes itself from other variants that often lead to lavishness and profligate resource use due to intricate finishes and embellishments.

Designing for the Future.

Aligned with eco-conscious, cruelty-free, vegan, and sustainable brand movements, this design avenue gains robust backing. Pulp packaging aptly addresses the aspirations of emerging consumer generations that uphold the ethos of “less is more.” Its impact is evident from the very first impression, underlining its unwavering commitment without any deception.”

From a broader perspective, what are the macro-trends affecting the world of packaging design?

Juan Campdera:

“Environmental Responsibility.

Plastic pollution stands out as a critical environmental concern, with extensive evidence showcasing its contamination of water bodies, wildlife, and adverse effects on human health. Plastic packaging significantly contributes to this global crisis, driving the demand for fiber-based alternatives that are free from plastic.

Compostable Nature.

Pulp packagings, being products of organic materials, are naturally biodegradable and suitable for composting. If not properly recycled, they naturally break down upon exposure to the environment and moisture, much like other organic material.

Recycling Efficiency.

Molded pulp packaging operates within a robust closed-loop system. Crafted from recycled fiber materials, it seamlessly integrates into the recycling process alongside paper and cardboard materials, contributing to efficient resource utilization.

Trimming Material Use.

This packaging type ingeniously shapes its self-supporting structure to match the pack’s form, curbing the material required for its creation. This innovation drastically reduces material waste during its manufacturing process in many instances.”

기사원문링크>

https://designwanted.com/molded-pulp-alternative-packaging-juan-campdera/