custom built wood fired kiln for firing terracotta

custom built wood fired kiln for firing terracotta

5-tier TCS system after glazing

5-tier TCS system after glazing

View more

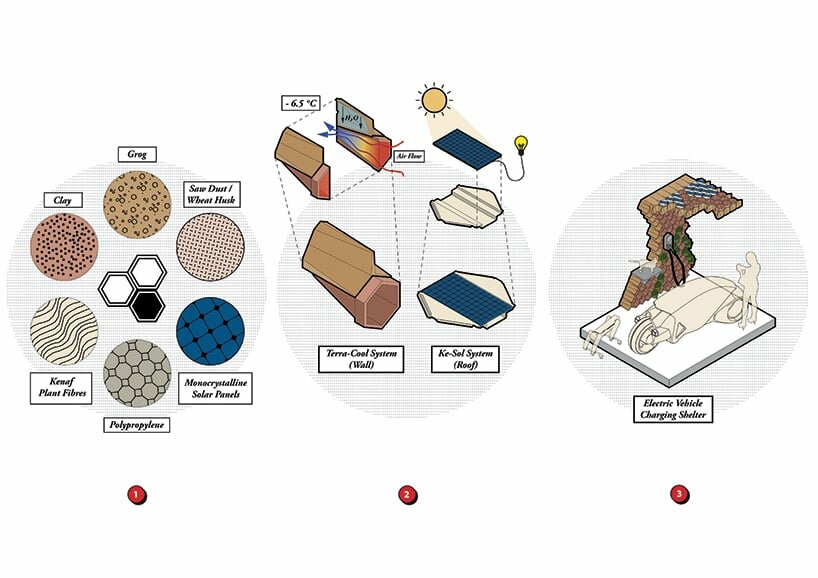

Lo-Hi Tech project by Studio SKLIM embraces high and low technologies to craft innovative hybrid solutions that are not only efficient and sustainable but also address pressing environmental issues and improve human living conditions. The project is a layering of trajectories, exploring how primitive materials can be future-proofed with technology and igniting material system cross-overs between shelter and vehicular infrastructure. The research demonstrates the immense potential for sustainable solutions to contemporary challenges by combining Asian primitive materials with both modern and ancient technology. Additionally, it highlights the convergence of traditional craftsmanship with innovative techniques.

The research focuses on two main building material systems: Ke-Sol System (KSS) – Kenaf Fibre Biocomposites x Solar Panel System and Terra-Cooling System (TCS) – Terracotta x Evaporative Cooling Water + Sand Filter System. The Ke-Sol System (KSS) seamlessly blends the strength of Kenaf fibers in lightweight biocomposite roof tiles with custom solar panels. Through a meticulous process involving high thermal pressure, Kenaf fiber mats are molded into robust yet lightweight roof panels. These panels are then integrated with monocrystalline solar panels, creating an innovative roof tile capable of generating clean energy through its modular and tiltable configurations. This integration showcases a harmonious fusion of nature and technology.

removing terracotta pieces from kiln | images by Ong Chan Hao / Arun K R / Studio SKLIM

removing terracotta pieces from kiln | images by Ong Chan Hao / Arun K R / Studio SKLIM

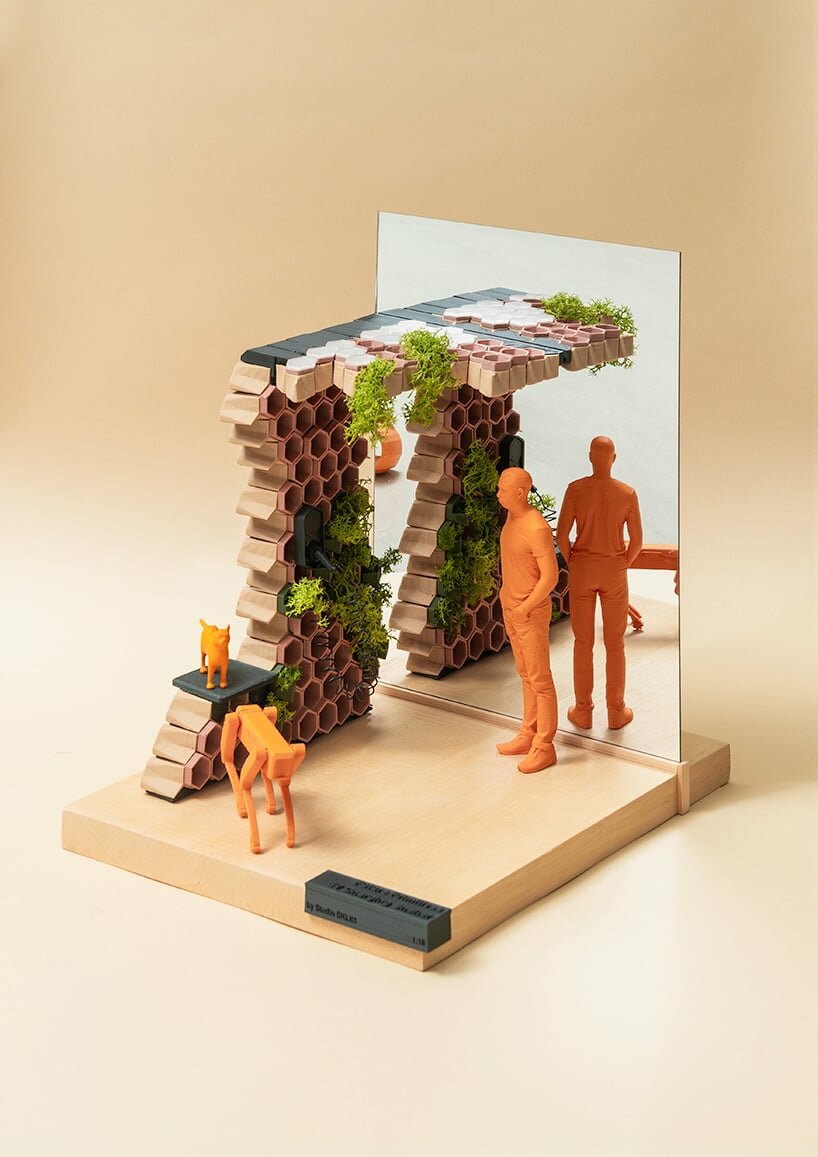

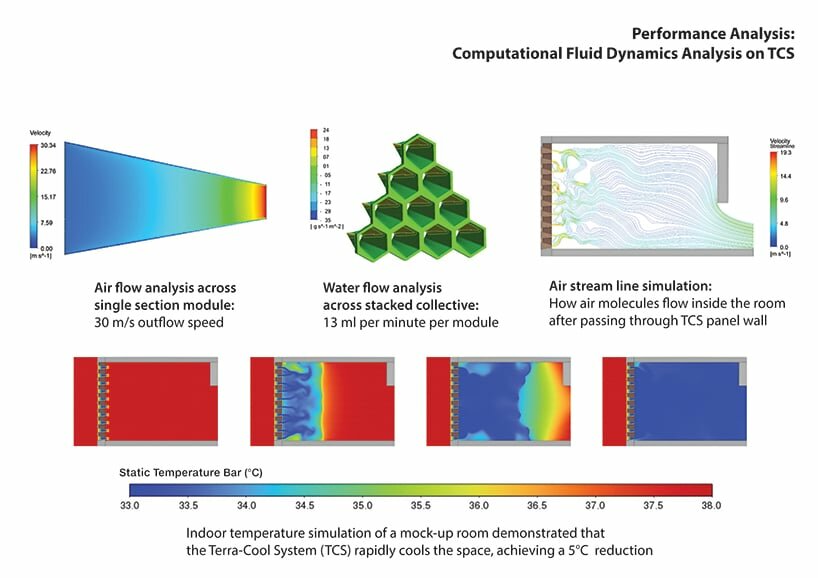

The Terra-Cooling System (TCS) harnesses the natural properties of abundant terracotta, drawing from ancient refrigeration (Zeer pots) and irrigation (Olla Pots) techniques. Comprising two main structural modules—Hex and Tri components—the Hex converts hot air into cool air, while the Tri serves as a water tank, supplying water to the surrounding Hex. By integrating terracotta with innovative technology, TCS forms a wall system capable of reducing air temperatures by an impressive 6.5 degrees Celsius. This temperature drop is attributed to three key factors: the inherent cooling properties of terracotta, a meticulously designed form by Studio SKLIM that maximizes air and water flow, and the cooling effect driven by water evaporation.

plaster of Paris molds for dry slab casting of terracotta pieces

plaster of Paris molds for dry slab casting of terracotta pieces

Furthermore, Computer Fluid Dynamics (CFD) simulations refine the design for optimal evaporative cooling performance. The endeavor envisions a future in which material systems effortlessly transition between shelter and vehicular infrastructure, transcending borders. The fundamental premise of the research is the seamless integration of the built environment with vehicles, including energy sources and sustainable materials. One relevant scenario involves creating sustainable shelter infrastructure for Electric Vehicle (EV) charging stations. These structures not only reduce ambient temperatures but also harness solar energy for localized lighting during the night.

custom built wood fired kiln for firing terracotta

custom built wood fired kiln for firing terracotta

5-tier TCS system after glazing

5-tier TCS system after glazing

Terra-Cooling System (TCS)

Ke-Sol System (KSS) and Terra-Cooling System (TCS)

Ke-Sol System (KSS) and Terra-Cooling System (TCS)

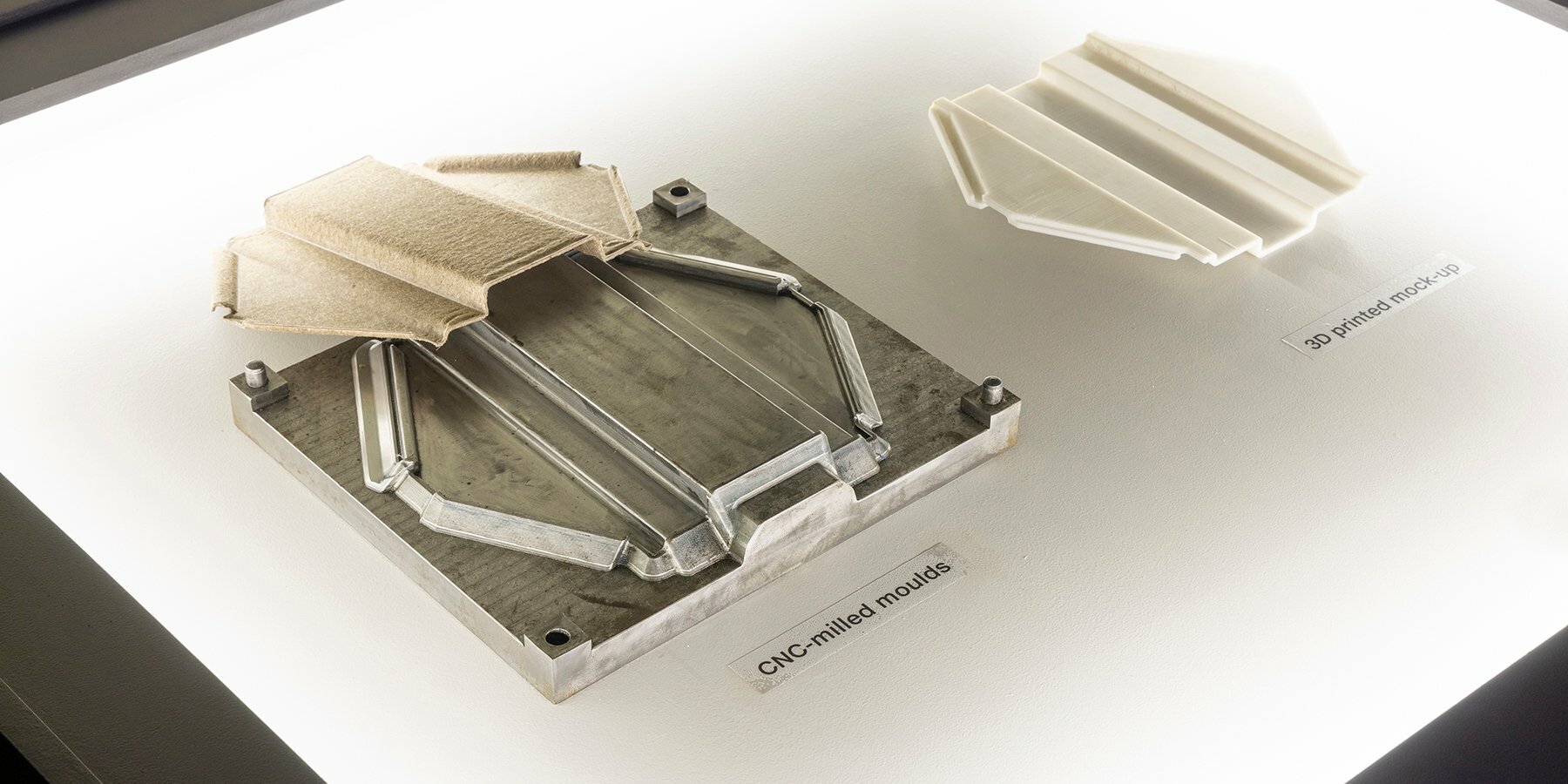

CNC-milled molds

project info:

name: Lo-Hi Tech. Primitive Materials: Future Frontiers

designer: Studio SKLIM | @studiosklim

design team: Kevin Lim, Ashwin Bafna

client: ZER01NE (Hyundai Motor Group)

photography: Ong Chan Hao / Arun K R / Studio SKLIM

edited by: christina vergopoulou | designboom