IN NIKE’S SHOEDOM, FOOTWEAR RECEIVES LIMITLESS LIVES

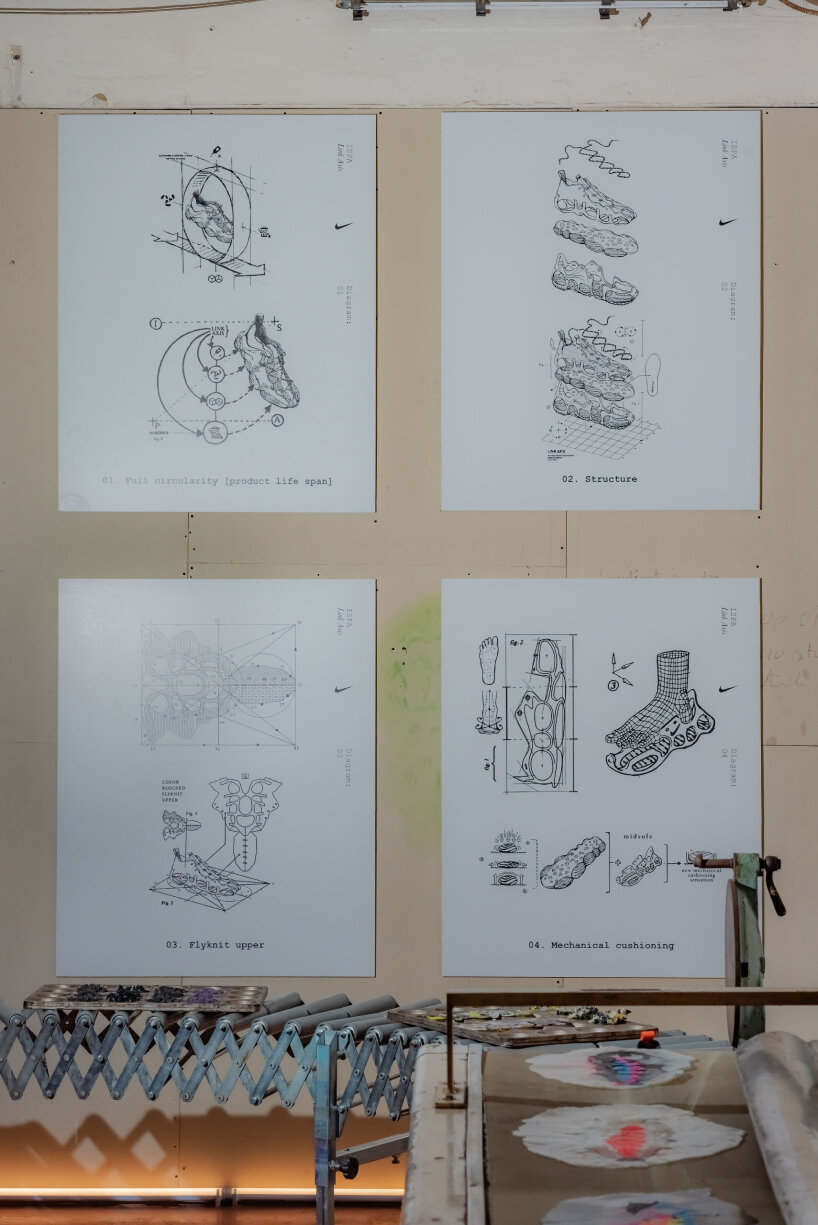

NIKE has branched out with a team of footwear designers that make, break, and remake shoes from recycled, repurposed, and revisited materials around them. It upholds the ethos of improvising to see what can be improved on the shoe design, scavenging for innovative processes and materials to unravel the repurposed kicks, protecting the new result from further causing environmental problems, and making these solutions adaptable enough for all situations. These ideals congregate into the acronym ISPA, the foundation of NIKE’s mission to design shoes that can be taken apart, pieced together into a new look, and repurposed properly.

During Milan Design Week 2023, designboom caught up with Shamees Aden, Senior Footwear Designer at ISPA, who told us the reason behind hosting an ISPA workshop inside a former bread factory in Viale Monza. ‘We were inspired by the idea of taking the different points of house baking, dissecting our design process, and displaying the journey of how we created our universe, design tools, and processes. It is not just having this nice, finished product, but also showing the full journey of how it began to exist,’ she tells designboom.

images courtesy of ISPA and NIKE

images courtesy of ISPA and NIKE

DESIGNBOOM INSIDE ISPANIFICIO

Inside ISPANIFICIO, Aden and a team of designers converted the bread factory into the temporary home of NIKE’s shoe-making exhibition. A footwear bakery open for all, visitors were ushered into a peek through the ISPA process from conceiving the design idea to bringing it to fruition. The exhibition spanned three rooms where the ISPA team individually showcased the working methods in place to form new shoes from old materials and objects.

ISPA MindBody shoes informed the visitors about the raw nature of materials and how waste could be eliminated from the get-go. Here, glues were stripped from the process as the ISPA incorporated cables to attach parts of the shoes together. Algae inks were infused on the surface of the shoes, and NIKE’s Flyknit material – strands of yarn that have been woven into a one-piece part of the shoes – showed up on the upper and padding underfoot, the latter offering the sensation of being barefoot on grass or pine needles.

NIKE invited visitors to customize their pattern pieces using algae inks and dyes that had been sourced locally or made from repurposed food waste. ‘We haven’t applied any glues to the shoes. Every piece is snapped together. You have a cording system that runs throughout the shoes, covering the lacing system. Then, they can get assembled and disassembled, and recycled in their waste recycling, which is a fascinating task,’ says Aden.

ISPA is the acronym for improvise, scavenge, protect, and adapt

ISPA is the acronym for improvise, scavenge, protect, and adapt

BIO-BASED PLASTIC FOAM FOR ‘ISPA UNIVERSAL’

Entering the next room, artificial intelligence took the limelight as the rapidly developing technology translated NIKE’s technical vocabulary into tangible footwear products. ISPA Universal shoes are made from bio-based plastic foam sourced from sugarcane which then gets molded and hand-buffed. NIKE injects cork insoles for this model and features replaceable parts to extend the product’s recyclable life. By employing digital tools, wearers can create their own 3D-printed molds to realize their personal designs.

‘This room is really about finding the future tools we can use to create new forms and shapes. Here, we used a digital tool and created an algorithm based on the idea of clashing together to allow us to experiment with the shapes during the ideation process. We also started thinking about the end life of the product, so when we finish this exhibition, you have these shoes that were built in the learnings taken from the ISPA MindBody, which is our modular system, and then apply these learnings into our ISPA Link Axis,’ Aden shares with designboom.

I:improvise to see what can be improved on the shoe design

I:improvise to see what can be improved on the shoe design

CIRCULARITY IN NIKE SHOE-MAKING JOURNEY

ISPA Link Axis concludes the shoe-making journey of ISPA, bringing up the proof that circularity can lead to new aesthetic frontiers. The earth-colored shoes in the NIKE series are identified by removable parts, mainly unplugging the upper from the soles.

The shoes can be completely disassembled at the end of their lives, making repurposing and reusing parts a breeze in the recycling process. In the bread factory, a conveyor belt sitting on top of abandoned baking equipment put up a show of reincarnating NIKE’s shoes from footwear to skateboard wheels, giving the old object a renewed purpose and reinvigorated second life.

‘What’s great about the materiality of these shoes is that they could be melted down and be used again. After that, you post the question ‘well, what should we do with this material?’ or ‘what is the second life of this product?’ We speculate a little bit of what it could be, but we do want to imply the audience to come to us and tell us what we should do,’ Aden continues to tell designboom.

S: scavenge to find the best processes and materials by seeking innovation;

S: scavenge to find the best processes and materials by seeking innovation;

COLLABORATION AT THE CENTER OF NIKE ISPA

In NIKE’s ISPA shoedom, creativity and resourcefulness are at play where collaboration takes up part of the center stage. ‘I feel like we need to collaborate more with each other. I think you see that a lot when you have these brands that are working together and trying to find better solutions. We all have different expertise, so let’s figure this out together,’ says Aden, who believes that through collaboration, a fruitful result comes through.

An example she elaborates with designboom is when she and the ISPA team worked with scientists to look into how they could apply algae first into printers than to textiles. The latter developed an algae-based ink that the former could use to create ISPA MindBody so that NIKE wouldn’t have to use petroleum-based ink. ‘I feel like it’s seeking out those kinds of opportunities and collaborating together where you can create something much more sustainable,’ says Aden.

P: protect the reformed shoes from further causing environmental problems

P: protect the reformed shoes from further causing environmental problems A: adapt all solutions to make to fit broader potential

A: adapt all solutions to make to fit broader potential in Nike’s shoedom, creativity and resourcefulness are at play where collaboration takes up part of the center stage

in Nike’s shoedom, creativity and resourcefulness are at play where collaboration takes up part of the center stage