View more

In an era where sustainability is paramount, bioplastics have definitely emerged as a beacon of innovation in material science. They contribute to circularity in material design by reducing reliance on finite fossil resources and minimizing environmental impact associated with their manufacturing, thanks for example to the addition or substitution of constitutive elements deriving from renewable biological sources.

Among many actors in this trending field, French company Natureplast has been offering a diverse range of bioplastic compounds formulated with many different compositions.

Generally speaking, we refer to bioplastic compounds as to all of those plastic materials that have been produced starting from biomass-deriving building blocks, that contain some amount of bio based content, such as agricultural or food waste, or that can eventually biodegrade thanks to the activity of some microorganisms in determined conditions. Please note that currently, not every bioplastic compound features all these properties at the same time.

In this context, bio-based plastics like bio-based PP (polypropylene) and bio-based PET (polyethylene terephthalate) or PU and TPU (polyurethanes), stand alongside biodegradable plastics such as PLA (Poly Lactide) and PHA (Poly Hydroxy Alcanoate), all with or without the addition of some sort of natural fillers, offering a diverse range of properties to meet various industrial needs.

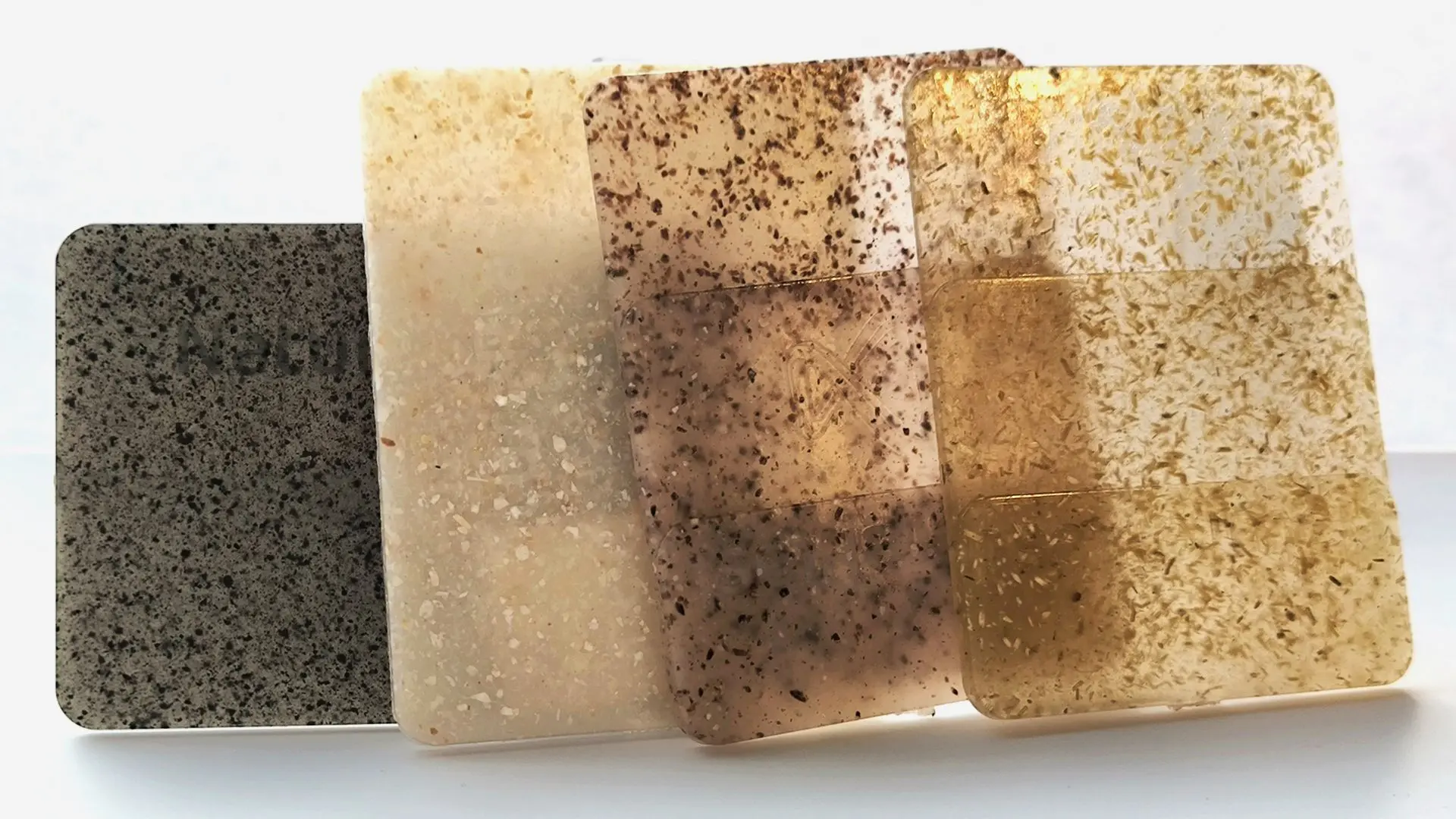

Such plastics can integrate a large variety of waste materials, so they can also be seen as a partial contribution to circular economy practices, as they repurpose secondary raw materials to a new life. Rice husk, for example, is rich in cellulose and can be processed into bioplastic with good mechanical properties. Scallop and mussel shells, composed mainly of calcium carbonate, can be used to reinforce their strength and overall durability.

Waste bricks, when ground into fine particles, can act as fillers in bioplastic composites, improving their structural integrity. Grape pomace, the residue from wine production, contains polyphenols and fibers that can be added to the compounds to create new and interesting color nuances.

The advantages of such materials are numerous, including reduced carbon footprint, decreased reliance on fossil fuels, enhanced biodegradability and new aesthetics. However, in some cases challenges remain, such as the current technico-economic performance compared to traditional plastics and the need for industrial-scale adaptation. Despite these hurdles, the benefits of bioplastics in terms of marketing, communication, and increasingly improved technical performance are driving their growing adoption across industries.

Bioplastics based on PP, PE, PU or TPU, PLA etc, also in flexible form, can be innovatively used in various design objects in furniture, home decor, packaging, fashion accessories or even consumer electronics, as standard processing methods such as injection molding, extrusion, and 3D printing can be employed to shape these bioplastics, allowing for intricate designs and customization.

Applications include durable and aesthetically pleasing decorative elements for chairs, tables, lamps, or for wearable items like shoes and bags, covers or cases for phones, tablets and other objects. The incorporation of waste materials can add unique textures and visuals to the surface, or can also be hidden by tuning the fillers dimensions and percentage in weight in the compound, together with the addition of standard dyes.

For those interested in integrating Natureplast’s bioplastics into their projects, the company offers comprehensive support, from the inception of an innovative idea to its industrial realization. The company provides a full range of unprocessed bioplastic materials globally, as well as standard or customized bioplastic compounds, ensuring that clients’ specific requirements are met with expertise.

Bioplastic materials are more than just a sustainable choice; they can represent a shift in the paradigm of material usage in design. Embracing their application in their process, designers and manufacturers can contribute to a more conscious future while benefiting from the technical and marketing advantages these materials can offer. As companies continue to explore the possibilities of bioplastics, we’ll continue to track the progress of innovation and environmental stewardship in the material science landscape.

기사원문링크>

https://designwanted.com/bioplastics-design-applications-natureplast/