A Collaborative Effort Towards Sustainable Housing

The Institute for Advanced Architecture of Catalonia (IAAC) has recently completed the second phase of its groundbreaking 3D Printed Earth Forest Campus, a 100 square meter building prototype constructed entirely from locally sourced soil and natural materials. Documented by photographer Iwan Baan and located within the Collserola Natural Park near Barcelona, the project represents a significant milestone in developing sustainable, affordable housing solutions. See designboom’s coverage of the project’s first phase here!

Initially conceived as a prototype for an upcoming project in Tanzania, the campus evolved from a single earth-printed wall into a full-scale pavilion. This expansion was made possible through a collaboration with global architecture firm Hassell. The project directly addresses two pressing global challenges — the construction industry’s substantial carbon footprint, accounting for 39% of global CO2 emissions, and the worldwide housing shortage.

IAAC expands its 3D Printed Earth Forest Campus with a 100 square meter prototype | image © Iwan Baan

IAAC expands its 3D Printed Earth Forest Campus with a 100 square meter prototype | image © Iwan Baan

IAAC’s living Laboratory of 3D printed earth

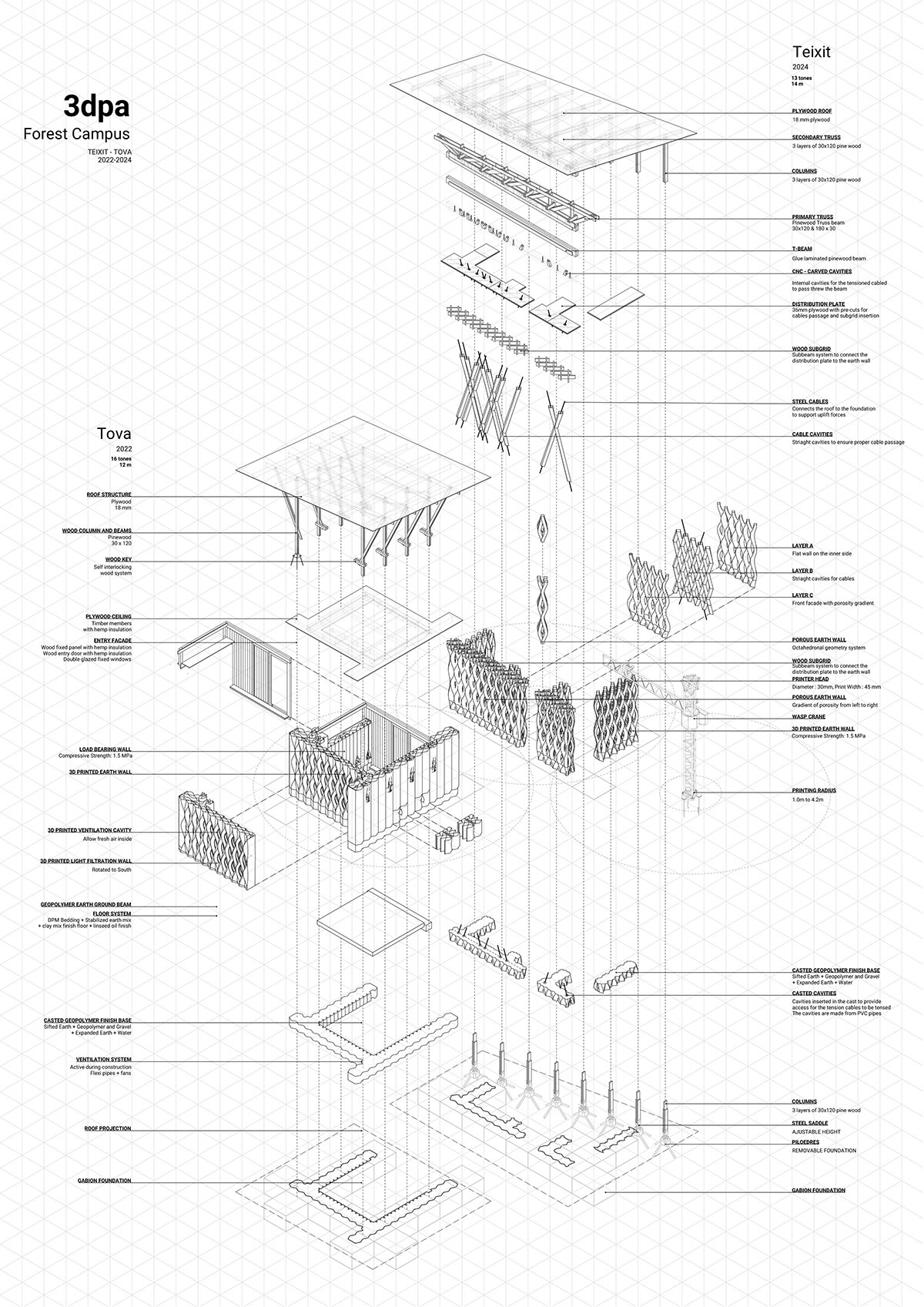

The 3D Printed Earth Forest Campus serves as a dynamic platform for experimentation and research by the team at IAAC. The building’s fragmented layout showcases the flexibility afforded by 3D printing technology, allowing for adaptable spaces that can be easily modified to suit changing needs. The campus is designed to create a diverse range of environments, from enclosed spaces to open-air areas, demonstrating the potential for personalized and adaptable architecture.

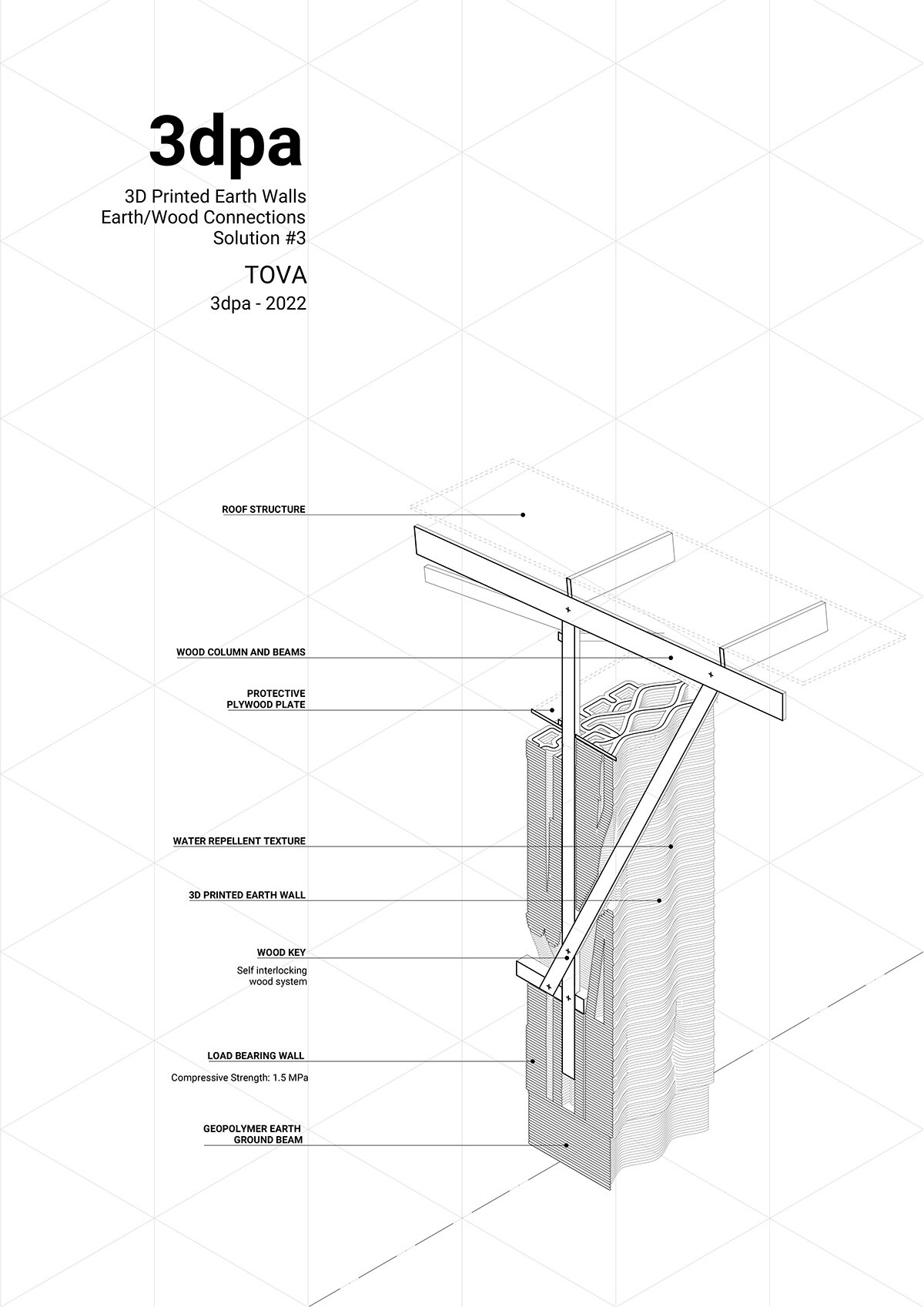

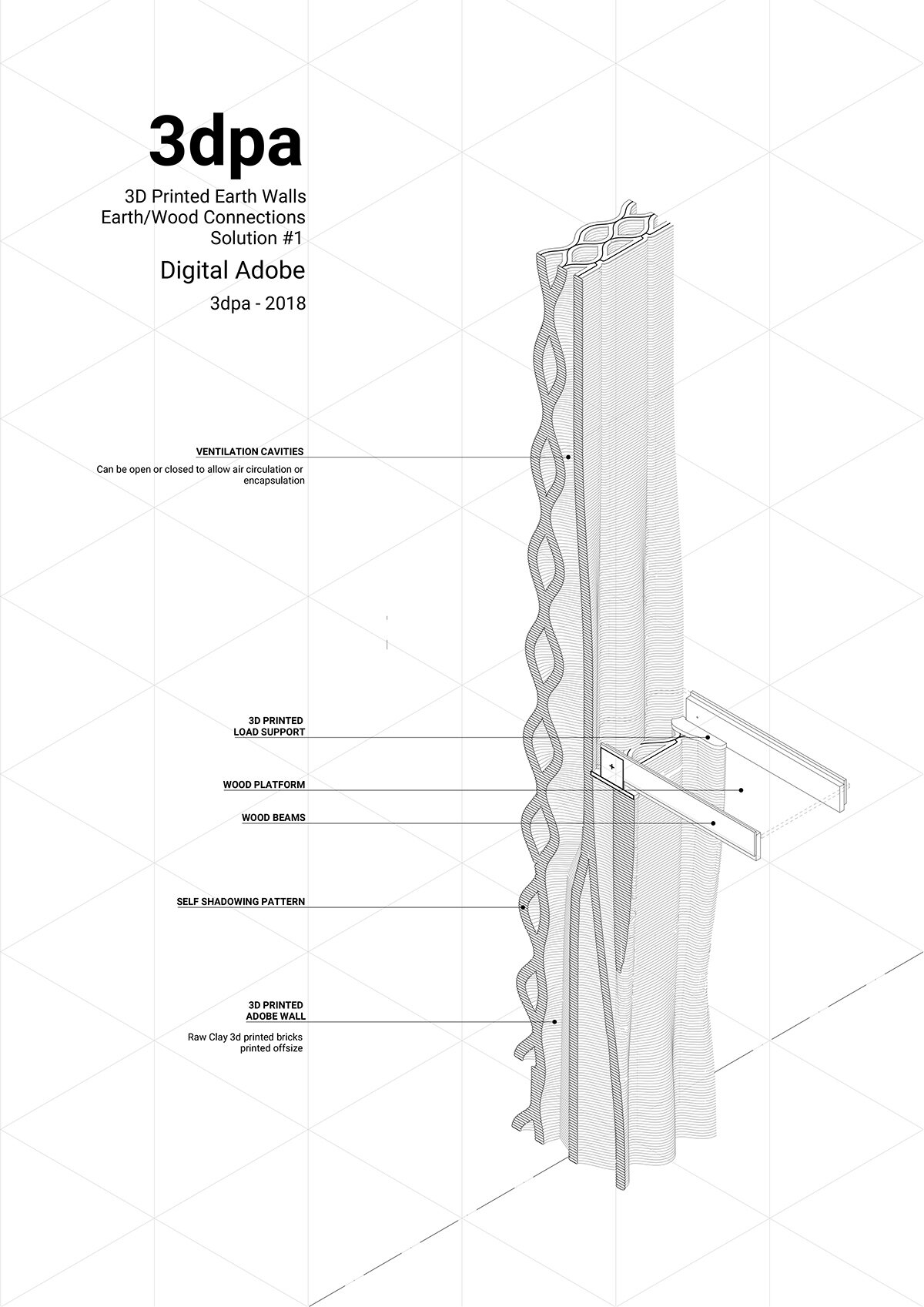

To minimize environmental impact, the campus is constructed primarily from natural materials. The foundation is made of natural stone, while the lower portion of the walls consists of a solid, stabilized earth base for protection against water damage. The main walls are 3D printed using earth excavated from the site, mixed with organic fibers and natural enzymes. This process is both efficient and sustainable, with walls reaching a height of 2.5 meters in approximately ten days.

the campus in Catalonia is a living laboratory for sustainable construction techniques | image © Iwan Baan

the campus in Catalonia is a living laboratory for sustainable construction techniques | image © Iwan Baan

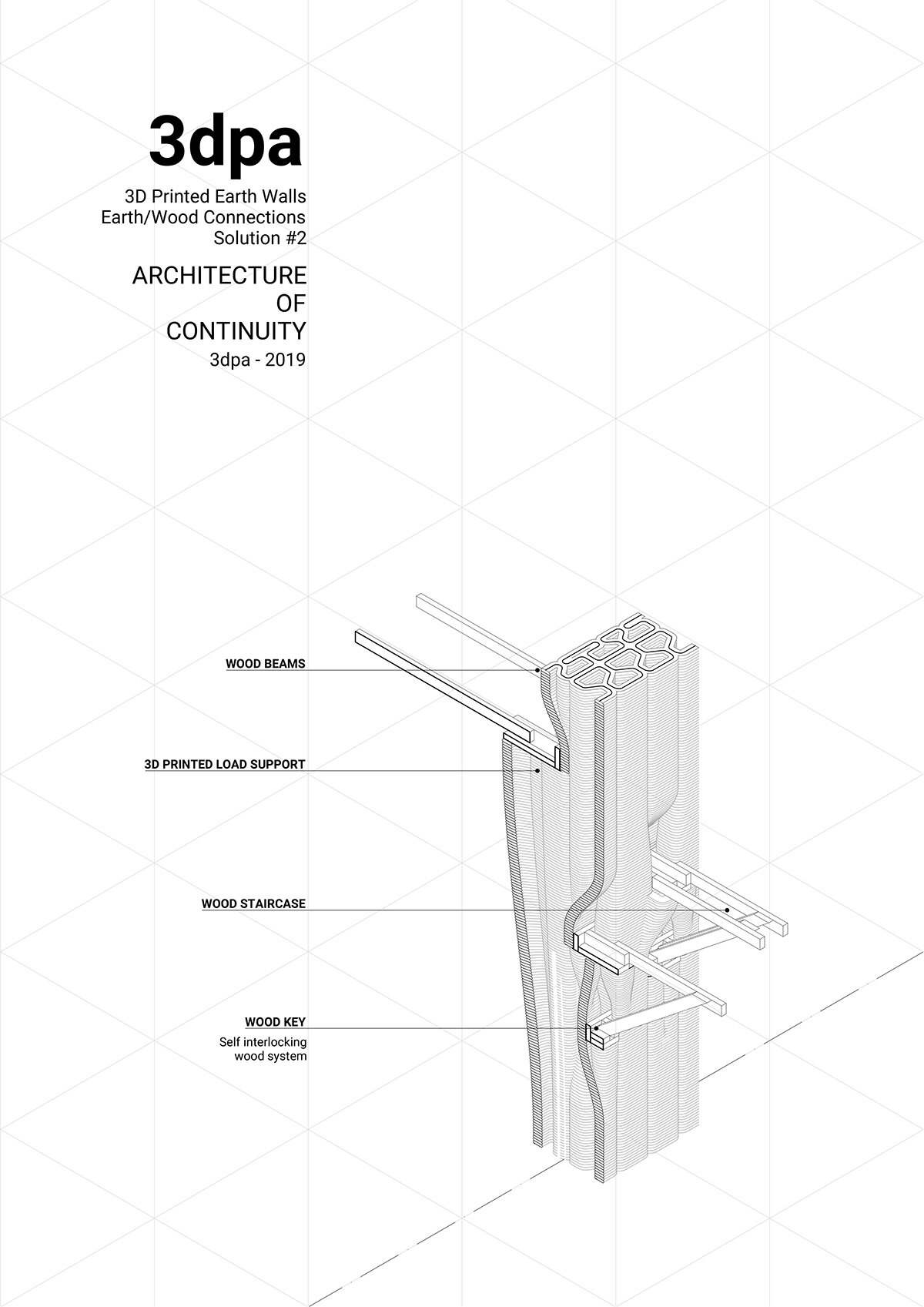

Optimized Wall Design for Performance and Efficiency

The 3D printing technique enables precise control over wall design, allowing for customization based on specific requirements. Walls can be configured to serve various functions, including structural support, thermal insulation, and natural ventilation. By incorporating hollow cavities within the walls, the project reduces material consumption while providing space for insulation and building services. The final wall thickness varies depending on load-bearing requirements and solar exposure. Through the 3D Printed Earth Forest Campus, the design and research team at IAAC has demonstrated the potential of earth-based construction to create sustainable, affordable, and adaptable housing solutions. As research and technology continue to advance, this project offers valuable insights into the future of architecture and construction.

the building is constructed from locally sourced soil and natural materials | image © Iwan Baan

the building is constructed from locally sourced soil and natural materials | image © Iwan Baan

IAAC worked with Hassell to develop the project, which began as a prototype for a housing project in Tanzania

IAAC worked with Hassell to develop the project, which began as a prototype for a housing project in Tanzania

the campus showcases the potential of 3D printing technology to create adaptable architecture

the campus showcases the potential of 3D printing technology to create adaptable architecture

below the ground, 50 cm of natural stone foundation guarantees stability and drainage

below the ground, 50 cm of natural stone foundation guarantees stability and drainage