Scientists at the Nanyang Technological University, Singapore (NTU Singapore) have developed a method that can allow them to produce 3D printed concrete blocks that capture and store carbon dioxide. Cement is responsible for about eight percent of global CO2 emissions, according to a 2024 report by the World Economic Forum, to help solve the issue, the scientists at NTU use the problem as the solution.

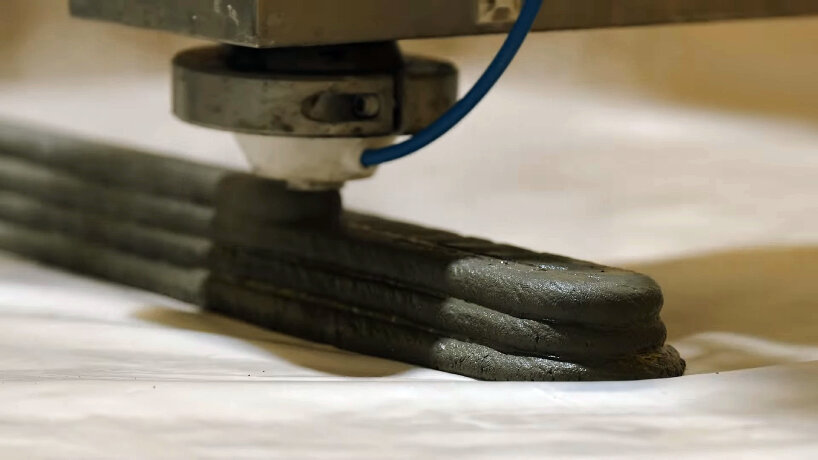

In their 3D printing method, they use steam and carbon dioxide captured as the by-products of industrial processes in the concrete mix. They find out that by directly incorporating and injecting the carbon dioxide and steam in the concrete, the cement blocks can capture carbon emissions, and they even improve their mechanical properties and maintain their robustness for construction use.

all video stills courtesy of Nanyang Technological University, Singapore

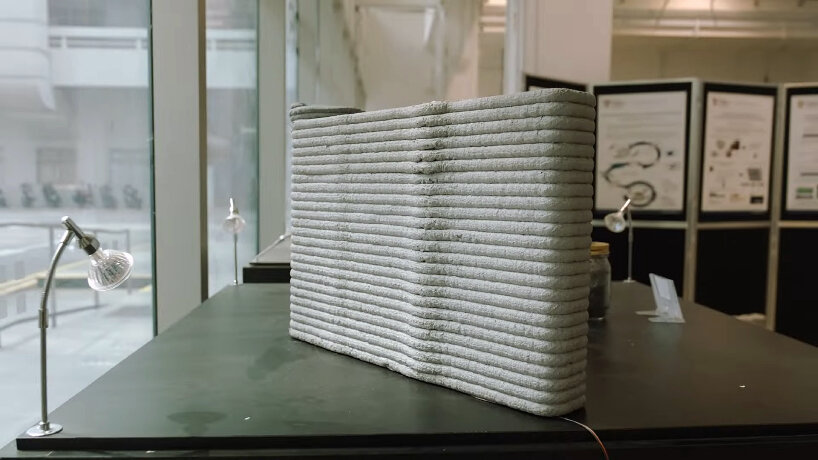

blocks that can hold more weight

In the study, the scientists at NTU Singapore detail their 3D printing method. They connect the 3D printer to carbon dioxide pumps as well as a jet that sprays steam on the surface of the wet concrete as soon as it is printed. The system then pumps carbon dioxide and steam into the concrete mix, and in the process, the carbon dioxide reacts with the components in the concrete. This turns it into a solid form, and the carbon dioxide stays locked inside. The steam comes in because this improves the absorption of carbon dioxide into the 3D printed concrete blocks.

During testing, the scientists find that the created concrete blocks can capture and store carbon dioxide and can hold 36.8 percent more weight than the conventional concrete blocks. The method has also shown a 50 percent improvement in printability, meaning that the wet concrete can be shaped and printed more efficiently, if desired. The 3D printed concrete blocks using this method have shown too that they are up to 45.3 percent stronger in bending, meaning how much they can flex before they break. These numbers are higher compared to the regular 3D printed concrete blocks. When it comes to absorbing carbon dioxide, the scientists say this method can trap 38 percent more carbon dioxide compared to traditional printing methods.

scientists at NTU Singapore develop a method to produce 3D printed concrete blocks that store carbon dioxide

these 3D printed concrete blocks can hold 36.8 percent more weight

the method uses steam from power plants in the process to improve the absorption of carbon dioxide

the method has also shown a 50 percent improvement in printability

the results have shown that the products are up to 45.3 percent stronger in bending

project info:

name: Carbon capture and sequestration with in-situ CO2 and steam integrated 3D concrete printing

institution: Nanyang Technological University, Singapore | @ntu_sg

study: here

emission report: here, courtesy of the World Economic Forum