View more

Concrete, once confined to construction sites and infrastructure projects, has emerged as a revolutionary force in contemporary product design. This versatile material now extends far beyond traditional building applications, finding its way into everyday items from speakers to furniture. Its adaptability in construction – from structural elements and flooring to wall panels and countertops – has paved the way for innovative applications in industrial design, challenging conventional material choices.

Recent technological advancements have transformed concrete’s aesthetic potential, introducing unprecedented colors, textures, and finishing possibilities. These innovations, coupled with growing interest in sustainable materials, have propelled concrete into the spotlight of modern design. As designers and manufacturers embrace its unique properties, concrete has become increasingly sought-after for its ability to blend industrial charm with sophisticated functionality, marking a new era in product development.

Concrete’s remarkable moldability stands as its defining characteristic, offering designers unprecedented creative freedom in product development. This inherent plasticity allows the material to be shaped into virtually any form, from sleek, minimalist furniture to intricate decorative pieces. Unlike traditional materials that require complex manufacturing processes, concrete can be poured into custom molds, making it an ideal medium for both mass production and bespoke designs.

The material’s adaptability particularly shines in outdoor applications, where its durability complements its formability. Designers leverage concrete’s moldable nature to create weather-resistant furniture, sculptural lighting fixtures, and architectural accessories that seamlessly blend form with function. This versatility, combined with modern casting techniques, enables the creation of pieces that range from brutalist-inspired benches to delicate, lace-like structures.

Inspired by Brutalist architecture, a state-of-the-art concrete speaker features an exposed concrete base in monochrome, reminiscent of post-WWII structures, complemented by a vibrant orange top for a modern touch. Clever engineering allows concrete to replace traditional materials like wood or plastic, enhancing sound quality and durability. Designed by Duc, the Orange Concrete Speaker offers tactile interaction where one can tap to open and activate or power off. This maintains the robustness of its construction material.

The Concrete Sector watch represents a masterful fusion of industrial aesthetics and precision engineering, marrying raw ‘béton brut’ concrete styling with sophisticated Swiss automatic movement. This minimalist timepiece showcases concrete’s versatility in luxury accessories, featuring a stainless steel housing that protects its refined mechanics. Enhanced with Super-LumiNova technology for round-the-clock visibility, the watch bridges brutalist architecture’s bold simplicity with horological excellence, offering wearers a distinctive blend of contemporary design and vintage appeal.

Modern concrete manufacturing has revolutionized the material’s aesthetic potential, offering designers an extensive palette that transcends traditional gray. Advanced mixing techniques and innovative aggregates now produce finishes ranging from mirror-smooth to dramatically textured surfaces, while mineral pigments and specialized additives create rich colors spanning from warm terra cottas to cool slate blues. This versatility enables creators to achieve distinctive visual effects previously impossible with conventional concrete.

The material’s textural diversity has become a defining feature in contemporary design, with options including polished surfaces that rival marble, rustic finishes that echo natural stone, and unique patterns created through specialized casting techniques. These varied appearances, combined with concrete’s ability to incorporate different aggregates and surface treatments, provide designers unprecedented creative freedom in developing products that range from refined luxury items to raw, industrial pieces.

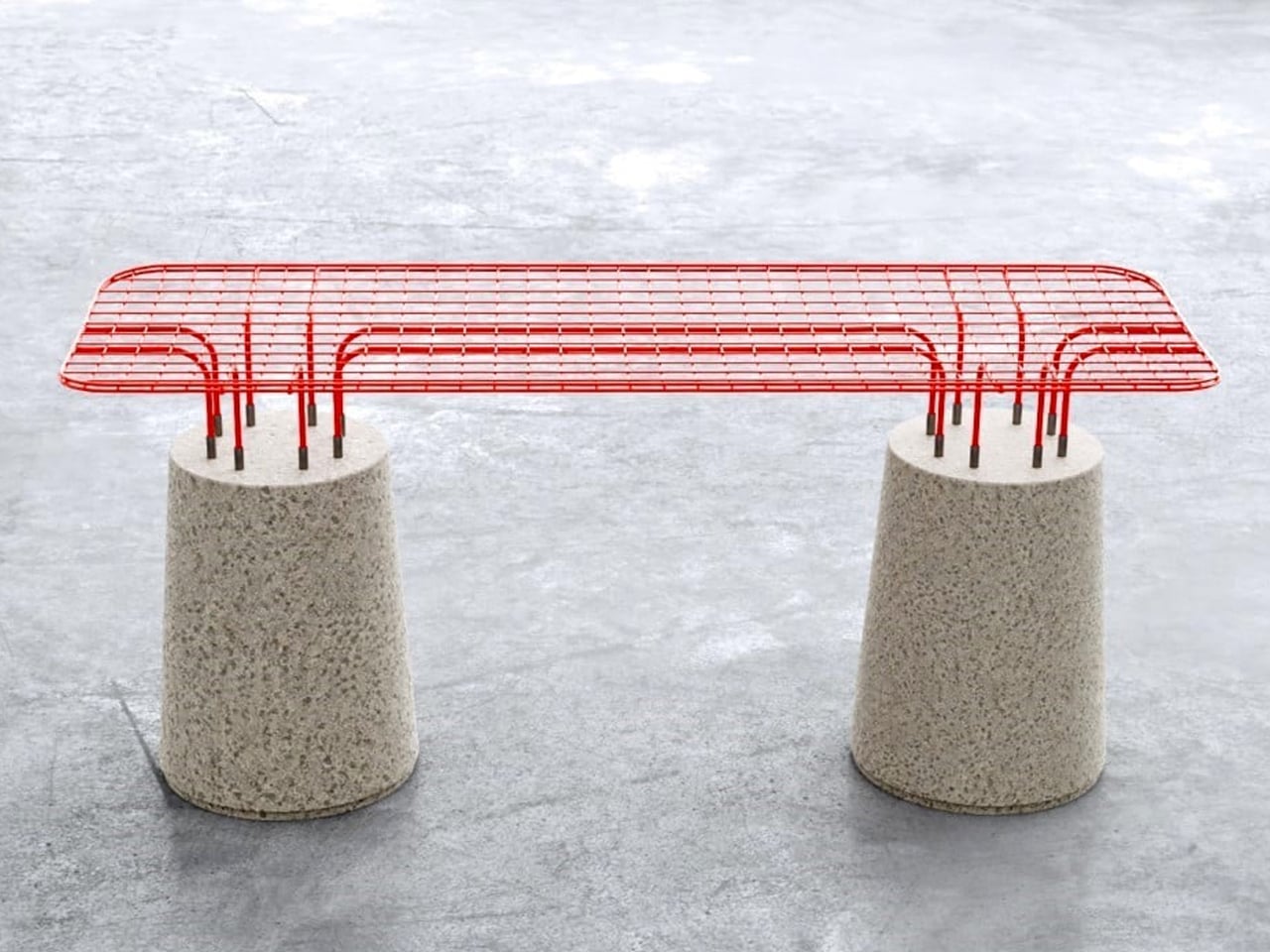

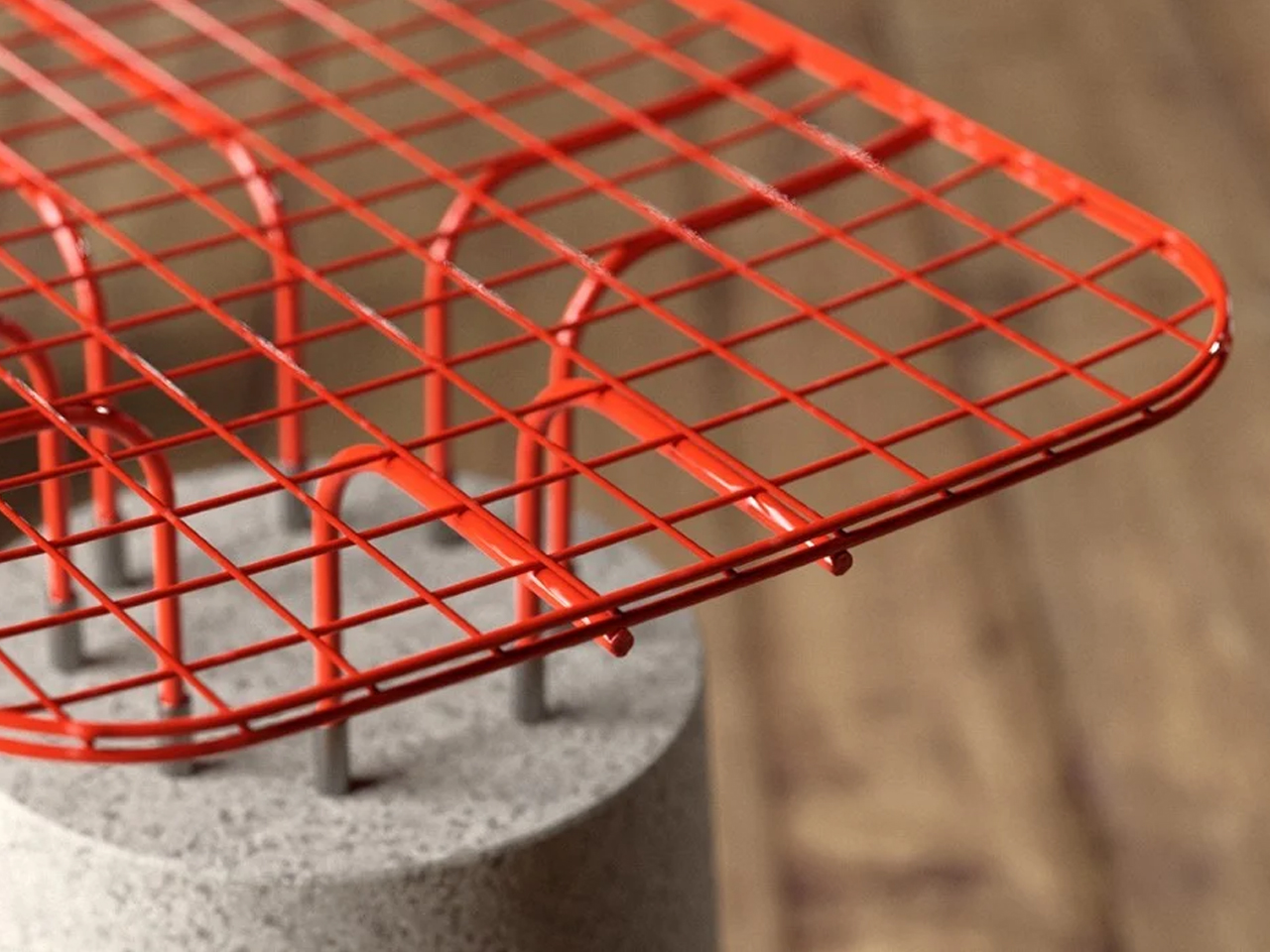

The MESH seating combines simplicity and visual contrast with its powder-coated metal wireframe plugged into a tapered cylindrical concrete base. Designed for both comfort and aesthetic appeal, it casts intriguing shadows and features vibrant colors that make it irresistible, especially for capturing the perfect photo moment.

Concrete’s inherent raw beauty has emerged as a defining aesthetic in contemporary design, captivating creators and consumers alike with its unrefined authenticity. The material’s natural imperfections – subtle air pockets, varying densities, and organic patterns – create unique surface characteristics that celebrate industrial honesty. This distinctive appearance, deeply rooted in brutalist architecture’s philosophy of exposed materials, has transformed concrete from a purely functional medium into a sought-after design element.

The material’s rugged charm particularly resonates in today’s design landscape, where authenticity and visual transparency are increasingly valued. Designers deliberately showcase concrete’s natural variations and surface irregularities, treating each imperfection as a mark of character rather than a flaw. This approach has elevated concrete’s status in premium product design, where its raw appeal offers a compelling counterpoint to mass-produced perfection.

CONECTO redefines concrete furniture with its modular stool system, blending flexibility and style. Featuring a base of high-strength UHPC concrete, it innovatively uses half-cylinder modules that can be combined like LEGO bricks to create various seating configurations ranging from simple stools to expansive benches. The addition of an acrylic top not only enhances its aesthetic appeal but also supports sustainability by promoting eco-friendly materials and designs.

Concrete’s understated elegance has become a cornerstone of minimalist design, where its clean lines and monolithic presence perfectly embody the “less is more” philosophy. The material’s inherent simplicity eliminates the need for additional ornamentation, creating spaces and products that speak through form rather than embellishment. This natural restraint aligns seamlessly with contemporary industrial design principles, where every element serves both aesthetic and functional purposes.

In modern interiors and product design, concrete’s minimalist character provides a sophisticated foundation for thoughtful compositions. Its neutral yet distinctive presence allows designers to create pieces that command attention through structural integrity rather than decorative excess. This approach resonates particularly well with current design trends that emphasize purposeful simplicity, sustainable materials, and honest expression of form.

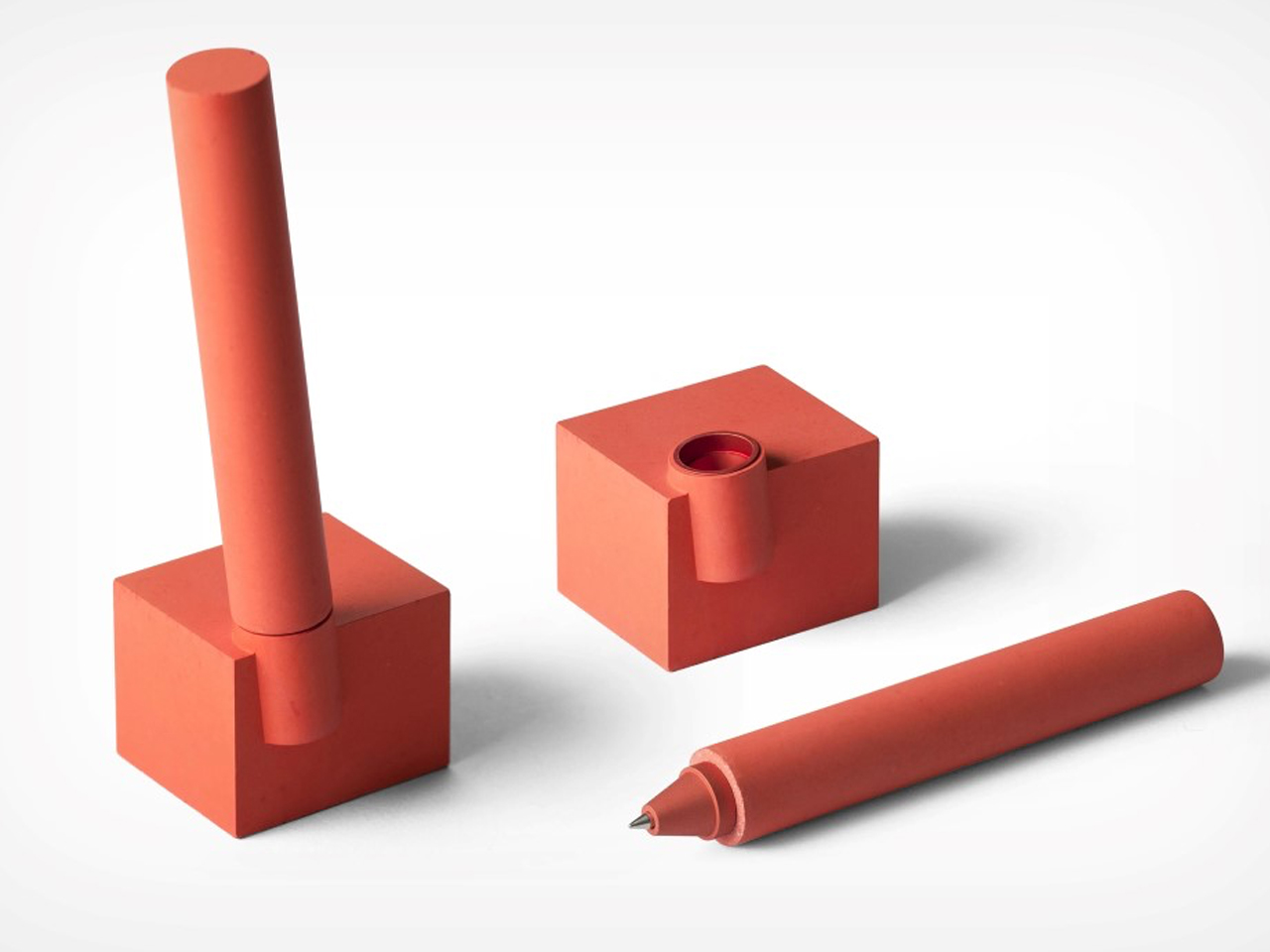

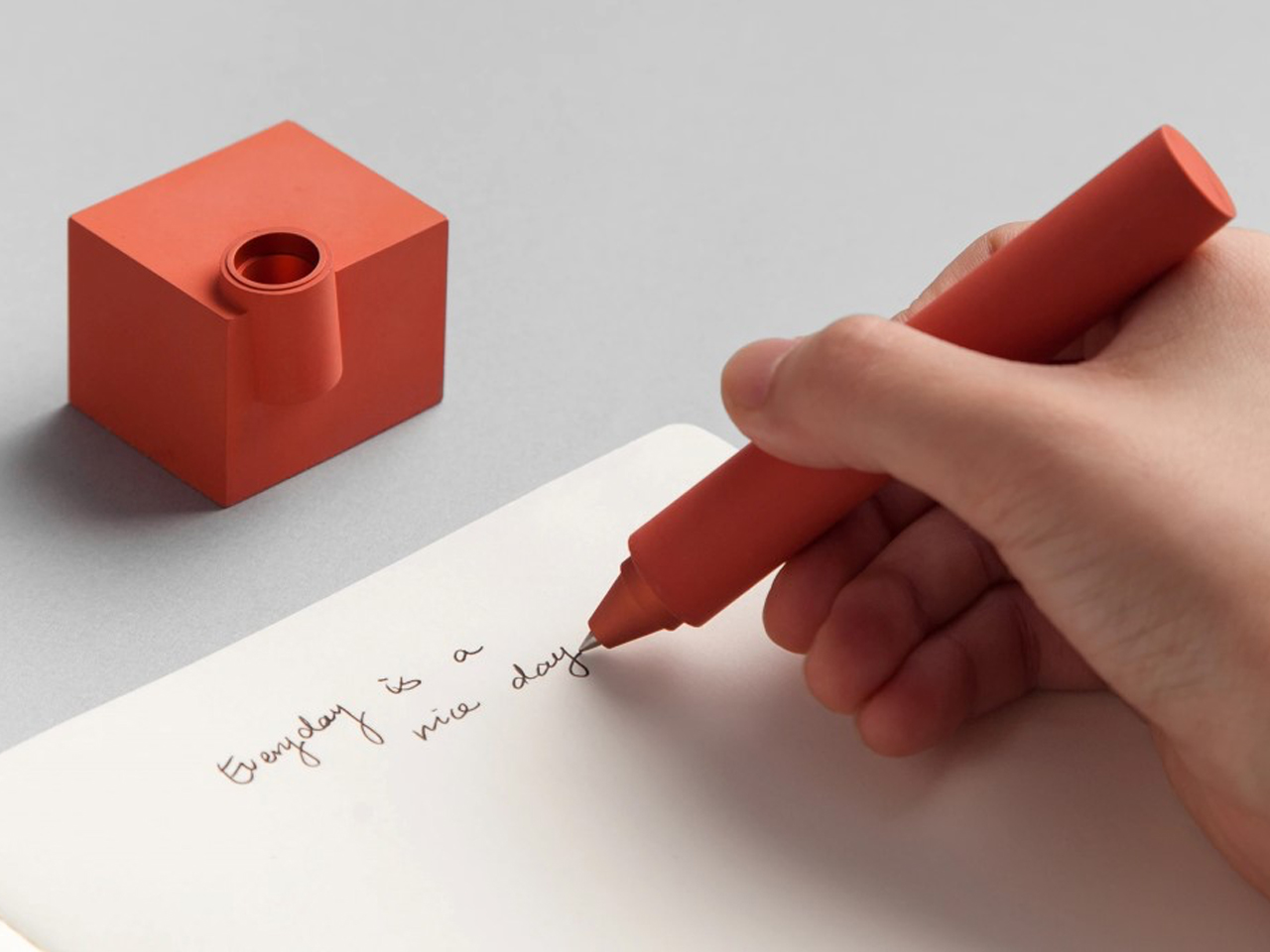

The Merge Desk Pen by 22 Design Studio showcases a uniquely simplistic form crafted from high-density concrete. Available in classic grey and eye-catching bright red finishes, it combines practicality with a poetic nod to construction and storytelling. The pen’s design, reminiscent of a quill in an inkpot, features a broad grip for comfortable writing and an overall minimalistic brutalist aesthetic that is sure to attract attention.

The sustainable transformation of concrete has revolutionized modern design through innovative recycling processes that give demolished structures new life. Rather than contributing to landfill waste, old concrete is now crushed, processed, and repurposed as aggregate for new construction and product development. This circular approach significantly reduces the environmental impact of concrete production while maintaining the material’s structural integrity and aesthetic appeal.

Leading manufacturers are embracing this eco-conscious evolution by incorporating recycled concrete into their design processes, creating everything from furniture to decorative objects. The movement toward sustainable concrete practices extends beyond mere recycling to include reduced-carbon manufacturing methods, alternative binding agents, and waste-incorporation techniques. These innovations position concrete as a frontrunner in environmentally responsible design materials.

The Waterbench harnesses rainwater in public spaces to sustain greenery, enhancing urban landscapes while moderating temperatures. It features a self-sufficient design with a porous concrete cover that collects rain, directing it to a reservoir of nourishing plants via a nylon cord. Made from permeable concrete, it holds up to 280 liters of water and supports easy planting, ensuring a green touch with minimal maintenance.

The “Brute” outdoor furniture series innovatively merges brutalist aesthetics with sustainability through its use of concrete, a durable and eco-friendly material known for longevity and minimal environmental impact. By prioritizing sustainable materials, Brute offers not only unique design but also a responsible choice for outdoor furniture that supports environmental stewardship.

Three-dimensional concrete printing represents a groundbreaking advancement in manufacturing technology, fundamentally transforming how designers approach product creation. This innovative process allows for the production of complex geometries and intricate patterns previously impossible with traditional concrete casting methods. From sculptural lighting fixtures to customized furniture pieces, 3D printing technology enables designers to push creative boundaries while maintaining structural integrity and reducing material waste.

The precision and flexibility of concrete 3D printing have opened new possibilities in both small-scale products and architectural elements. Designers can now create organic forms, hollow structures, and seamless transitions that defy conventional manufacturing limitations. This technology also offers significant advantages in production efficiency, allowing for rapid prototyping, customization at scale, and the ability to produce on-demand pieces without traditional molding constraints.

Holland, known for his skateboard-centric designs, recently collaborated with Skate Southampton to transform Guildhall Square into an expansive and visually striking skating area. His latest creation, the PSFF Bench, showcases sculptural appeal through 3D printing with concrete, serving as an innovative solution for global public skate furniture. This project underscores the growing influence of 3D printing in product design, supported by collaborations with Eindhoven University of Technology and BAM Infra to ensure high-quality construction. The minimalist, sports-centric aesthetic of the furniture collection highlights concrete’s durability and distinctive form, marking a significant integration of technology and design in the world of sports landscapes.

The convergence of concrete with cutting-edge technology has sparked a design revolution, yielding innovative products that challenge traditional material applications. From wireless charging stations embedded in concrete surfaces to smart furniture that integrates environmental sensors, designers are pushing boundaries by combining this ancient material with modern technological advances. These pioneering creations demonstrate concrete’s remarkable versatility in addressing contemporary lifestyle needs while maintaining aesthetic sophistication.

This material innovation extends beyond mere functionality, as designers experiment with concrete’s unique properties to create groundbreaking home décor and lifestyle products. Smart lighting systems utilize concrete’s thermal mass properties, while sound-dampening speakers leverage its acoustic characteristics. These innovations represent a new design paradigm where concrete’s traditional strength merges with smart technology to create products that are both beautiful and technologically advanced.

The Terrazzo Wireless Chargers by Bentu Design blend technology and architecture seamlessly. The W10 model features a terrazzo exterior made from recycled ceramic and quartz in white, green, blue, or orange. It doubles as a stylish coaster and Qi-compatible wireless charger with 5, 7.5, or 10W output options. After use, it can be disassembled and recycled, emphasizing sustainability with eco-friendly packaging.

The strategic pairing of concrete with contrasting materials has emerged as a defining trend in contemporary design, creating compelling visual and tactile experiences. When combined with warm elements like wood, concrete’s cool industrial character takes on new dimension and depth. This juxtaposition of materials – the smooth against the grainy, the manufactured against the natural – produces designs that challenge traditional aesthetic boundaries while maintaining functional integrity.

Designers are increasingly exploring these material combinations to create sophisticated products that leverage each material’s strengths. Glass adds transparency to concrete’s opacity, metal introduces sleek precision to its raw texture, and leather brings softness to its rigid structure. These thoughtful combinations not only enhance visual appeal but also improve functionality, as seen in furniture pieces that utilize concrete’s stability while incorporating softer materials for comfort.

This coffee table blends contrasting materials like natural wood and a novel, concrete-like material to create a sculptural aesthetic that balances warmth with coolness and solidity with flexibility. Its irregular wooden top is supported by conical legs crafted from a solid yet elastic mass, mimicking the appearance of concrete. Despite its artistic complexity, the table remains functional and sustainable, incorporating recycled materials while providing a durable surface for everyday use.

Cutting-edge manufacturing technologies are revolutionizing concrete production, introducing innovative alternatives that challenge traditional formulations. Scientists and engineers are developing advanced composites incorporating everything from recycled plastics to carbon-capturing materials, while new curing methods utilize artificial intelligence to optimize strength and durability. These technological breakthroughs have led to concrete variants that are lighter, stronger, and more environmentally sustainable than their conventional counterparts.

The manufacturing evolution extends to novel processing techniques that transform concrete’s fundamental properties. Researchers are experimenting with bio-based additives, nanomaterials, and smart sensors embedded within the mixture. These innovations enable the creation of self-healing concrete, temperature-responsive surfaces, and even carbon-negative formulations that actively reduce environmental impact. Such advancements represent a paradigm shift in how we conceptualize and produce concrete products.

Scientists at the University of Tokyo have pioneered “edible concrete,” a groundbreaking material that transforms food waste into a construction-grade substance. This innovative process repurposes common organic waste materials – including coffee grounds, banana peels, cabbage leaves, and orange skins – through a sophisticated manufacturing process involving dehydration, compression, and high-temperature molding. The resulting material exhibits remarkable structural properties, demonstrating strength levels three times greater than traditional concrete while maintaining resistance to biological degradation.

While technically consumable, this novel concrete alternative’s primary value lies in its environmental impact rather than its nutritional properties. By redirecting food waste from landfills and reducing the carbon footprint associated with traditional concrete production, this innovation addresses two critical sustainability challenges simultaneously. The material’s resistance to rot, fungi, and insects, combined with its superior strength, positions it as a promising alternative for sustainable construction and product design..

PLAEX-crete represents a revolutionary advancement in sustainable building materials, transforming the conventional concrete block through innovative recycling technology. By incorporating more than 90% recycled content from agricultural, marine, and industrial plastic waste, these blocks offer a compelling alternative to traditional cinder blocks. The resulting product achieves remarkable performance metrics, weighing 33% less while maintaining superior strength, demonstrating how waste materials can be engineered into high-performance construction products.

The system’s innovative interlocking design marks a significant evolution in construction methodology, enabling efficient assembly and disassembly for future reuse. While currently approved for non-structural applications, ongoing certification efforts aim to expand PLAEX-crete’s use in residential construction. This development could transform homebuilding practices by offering a sustainable, versatile alternative that addresses both waste management and construction efficiency challenges.

Sea Stone, an innovative material developed by women-led laboratory Newtab-22, represents a breakthrough in sustainable design by transforming seafood industry waste into a viable concrete alternative. This ingenious process harnesses the calcium carbonate-rich composition of discarded seashells, grinding them and combining them with natural binders to create a terrazzo-like material. The manufacturing process, deliberately maintained as a manual operation, ensures minimal environmental impact while maximizing the material’s unique aesthetic properties.

The resulting product offers designers a sustainable alternative that rivals traditional concrete in both functionality and visual appeal. Sea Stone’s versatility enables its application across various products, from decorative tiles and tabletops to sculptural vases, each piece showcasing distinctive textures and natural color variations. This innovation not only addresses industrial waste challenges but also demonstrates how circular economy principles can create aesthetically superior materials.

The concrete renaissance in modern product design illustrates how traditional materials can be reimagined through innovation and sustainable practices. From edible alternatives and shell-based composites to smart furniture and 3D-printed structures, concrete’s evolution continues to push creative and technological boundaries. As designers and manufacturers embrace these advances, concrete’s role in product design extends far beyond its conventional applications, promising a future where sustainability, functionality, and aesthetic appeal converge in remarkable new ways.

기사원문링크>

https://www.yankodesign.com/2025/02/14/modern-concrete-design-8-innovations-changing-home-and-office-products/